Aluminum Dip Brazing

How it works

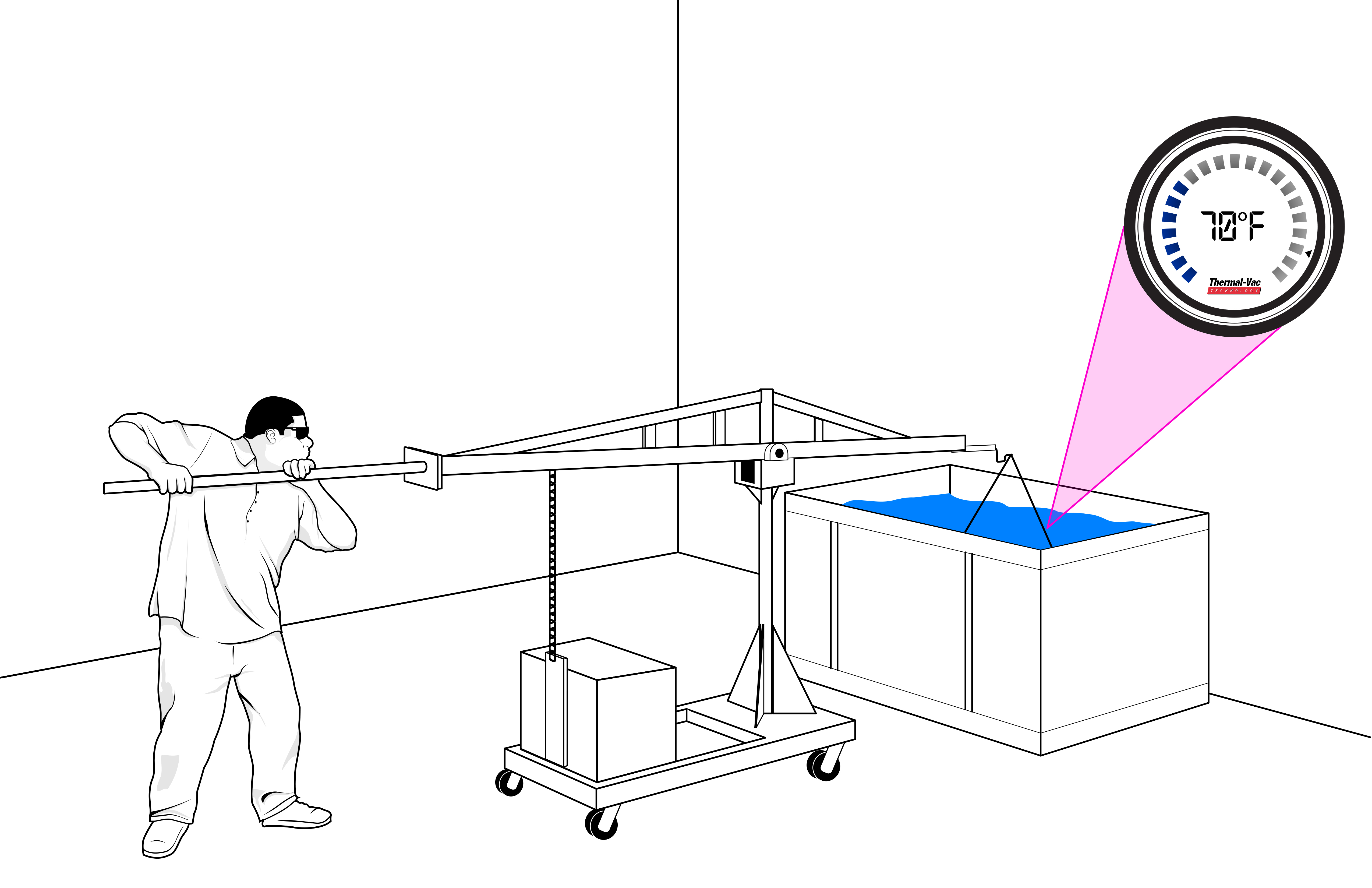

Step 2

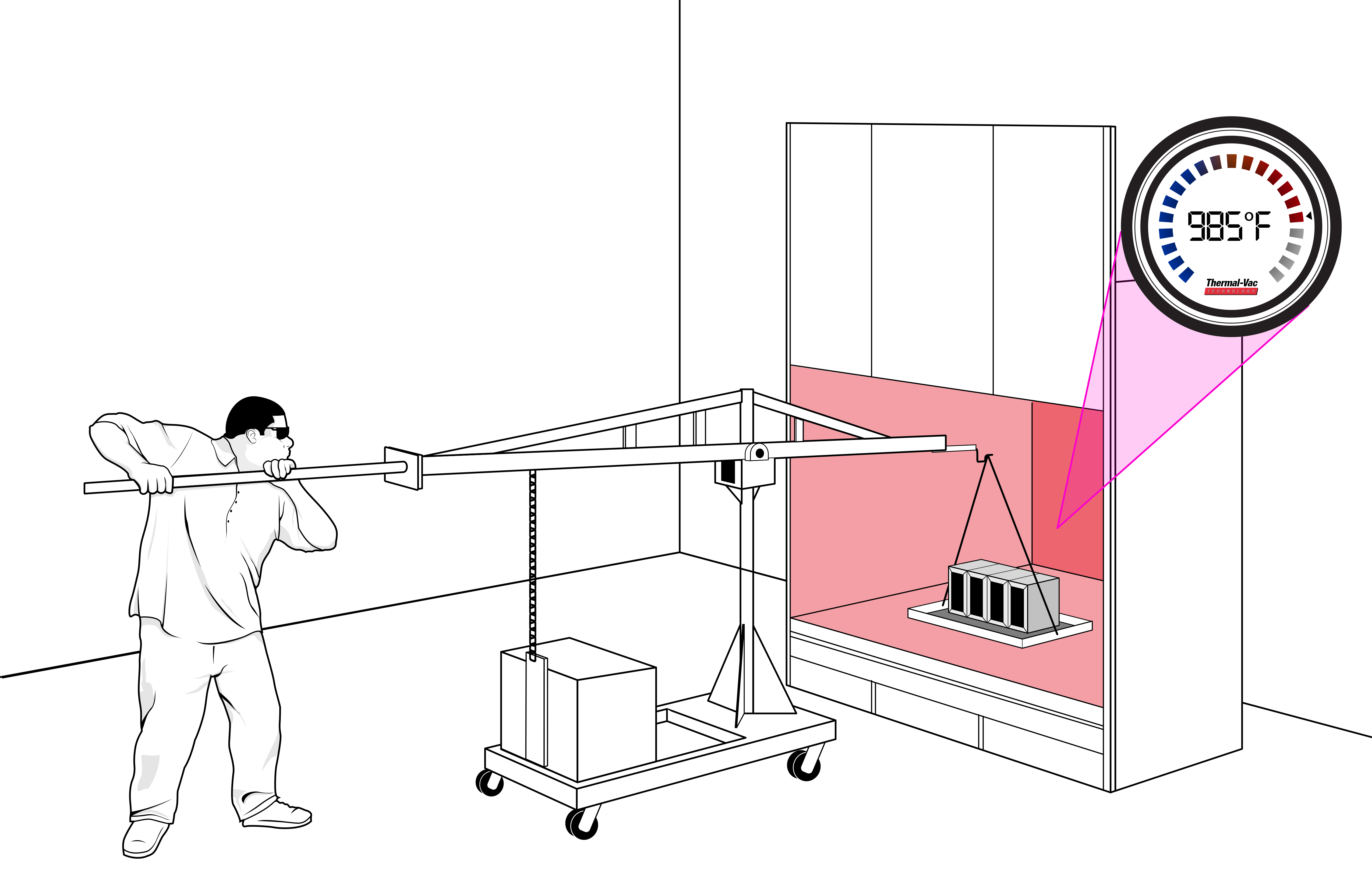

Preheat parts in an air furnace to prepare for dip brazing.

Step 3

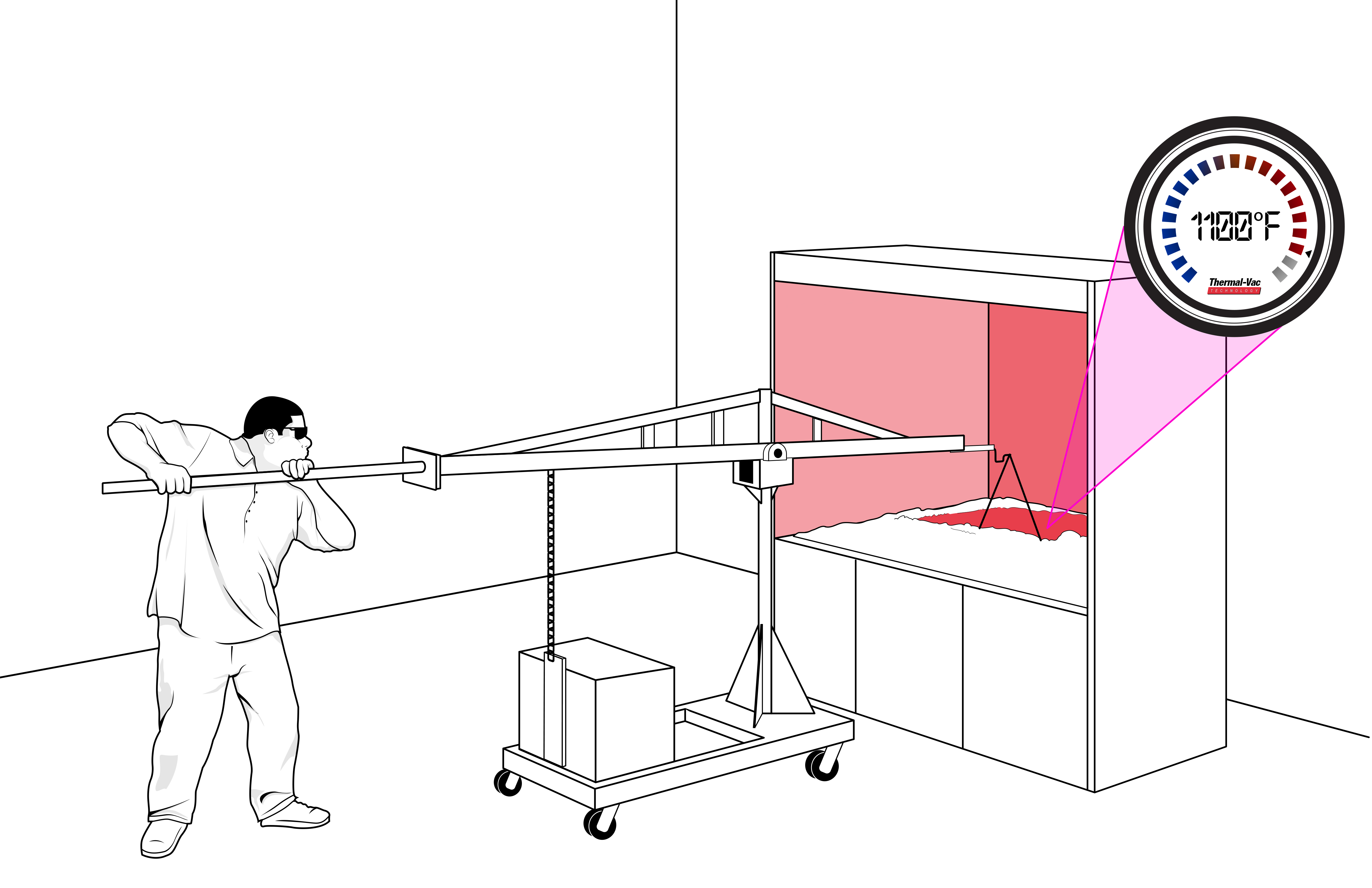

Immerse parts in molten salt bath to melt and flow braze alloy.

Step 4

Remove from bath to quench, clean and cool parts, aging in an air furnace as needed.

Benefits of Aluminum Dip Brazing

- It’s clean. The molten salts act as a flux, and protect the joints from oxidation. Once the residual salts are washed away you’re left with a beautiful product which requires little in the way of final cleaning or adjustments.

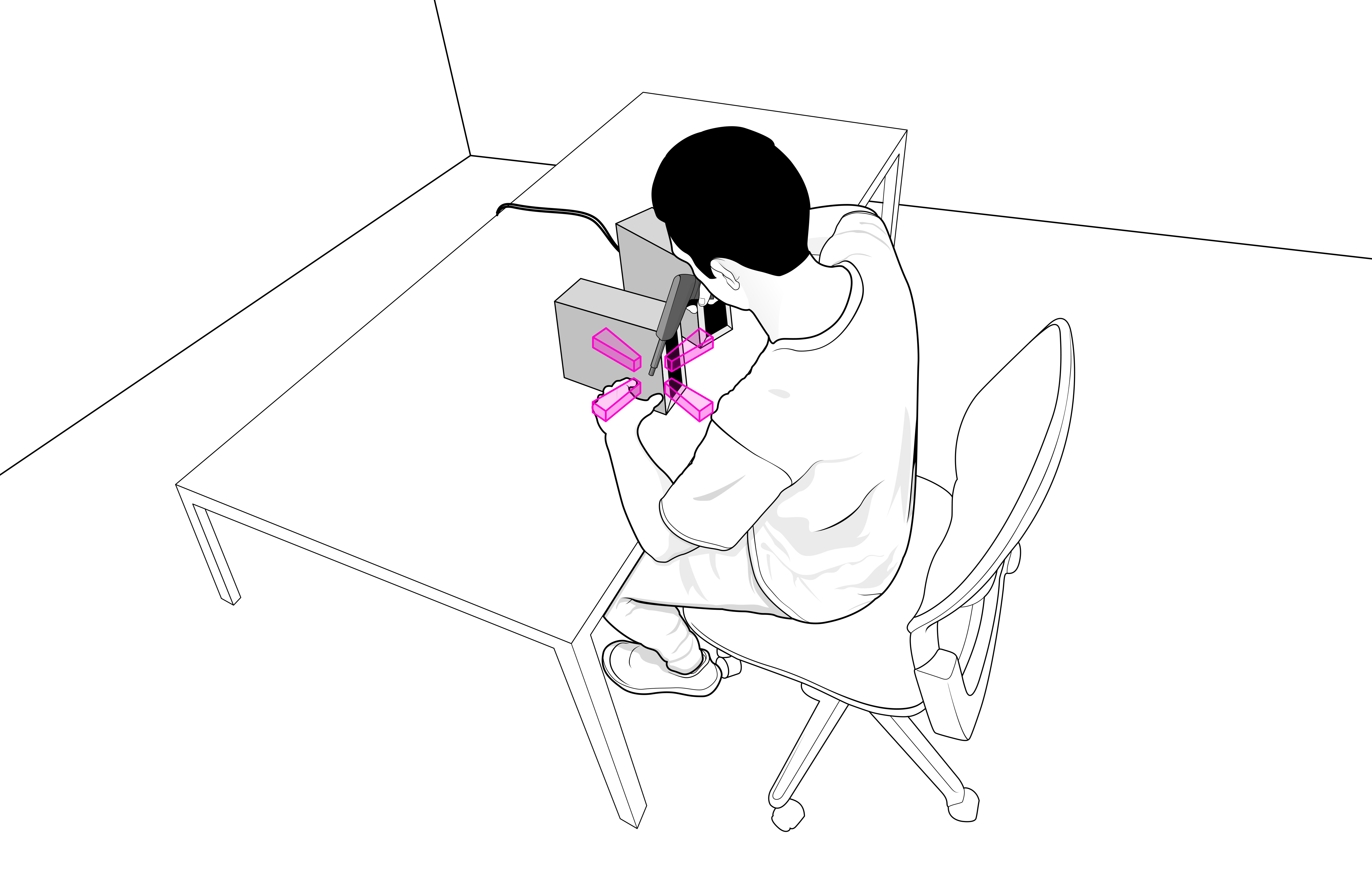

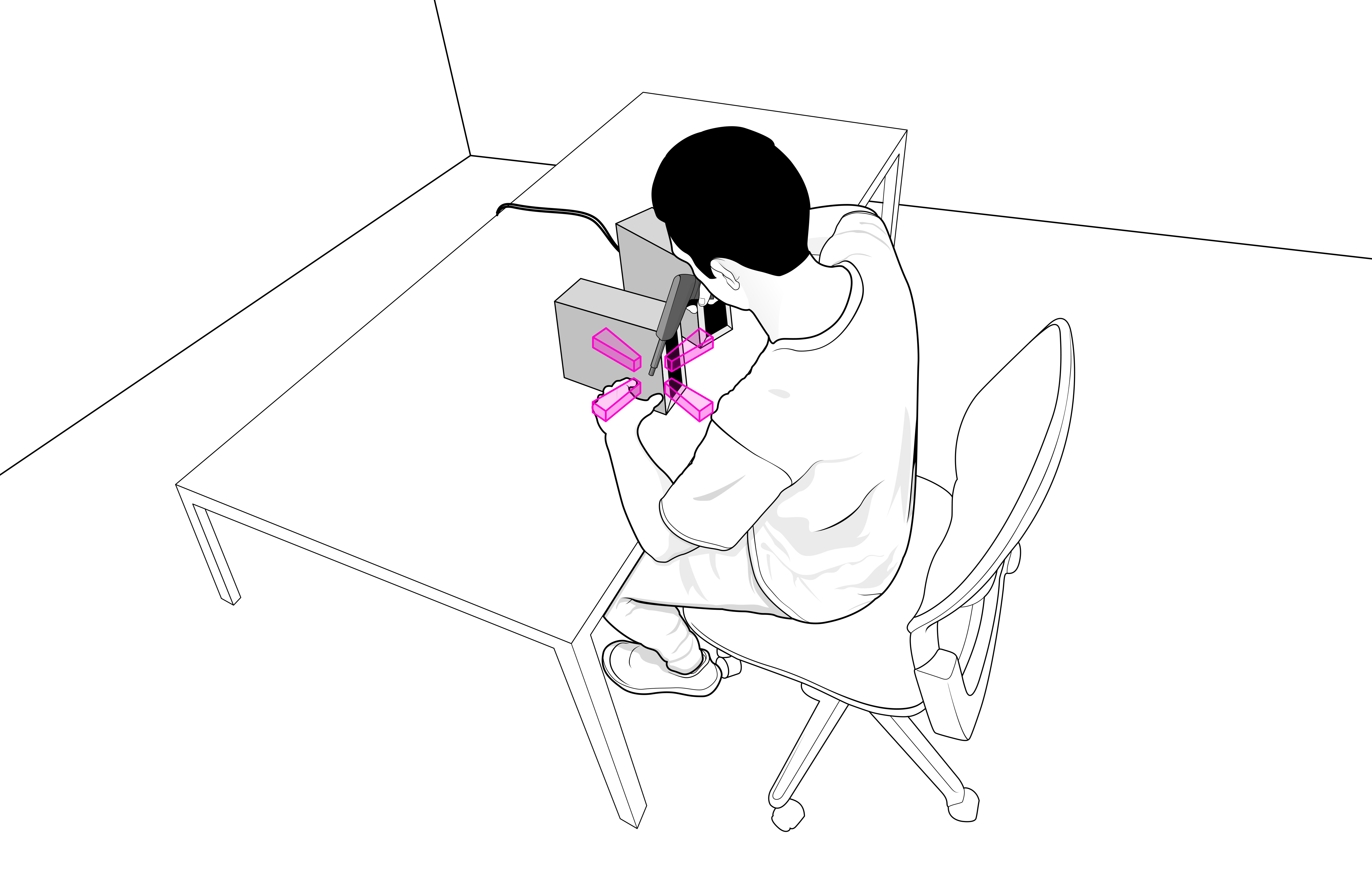

- It’s cost-effective. Aluminum Dip Brazing usually requires no expensive jigs or tooling. Instead, parts are designed to be self-locating and self-fixturing.

Quality of work and passion for what we do is what drives us.

WHERE Brazing WORKS

Medical / Dental

Some of the ways we provide world-class service to the medical industry include: Brazing of Dissmilar Metals (Metal to Ceramic, Titanium) High Temperature Brazing and Heat Treating (Temperatures Above 2400°F) Brazing to some of the most stringent cleanliness standards in the industry

Learn More

Engines / Propulsion

Our high-precision brazing, plating, heat treating, and coating/finishing products have been tested and proven in the guts of a rocket engine.

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating